Flexible motion solutions for modern Automation

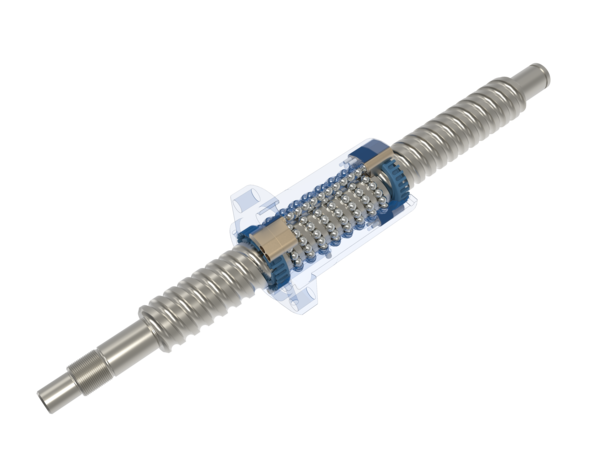

Automation systems operate in all kinds of conditions: cramped spaces, fast cycle times, shifting loads, and sensitive environments like cleanrooms or dusty factory floors. Ball screws handle them all with reliable, precise linear motion.

Whether it's assembly and handling systems, packaging machines, test benches, or fully automated production cells, ball screws are the go-to choice. They deliver smooth feed motion, accurate positioning, and repeatable performance, even during continuous and complex operations.

Engineered for both fine-tuned micrometer adjustments and dynamic high-speed movements, Steinmeyer ball screws combine precision, flexibility, and long-term durability. That’s why they’re trusted wherever motion matters most.

Let’s talk about your project!

Why choose Steinmeyer ball screws

Automated processes must run with absolute reliability — day in, day out, cycle after cycle. The performance of each component plays a critical role in the stability, efficiency, and quality of the entire system.

Ball screws from Steinmeyer do more than deliver precise linear motion. They ensure process stability, repeatable accuracy, and the flexibility needed to create innovative machine designs. With a wide range of variants and application-specific geometries, they’re the right fit for any challenge — from ultra-fast feed rates to finely tuned micromovements.

Smart engineering leads to more than just technical advantages. The right configuration for each application also ensures long-term cost efficiency throughout the entire product lifecycle.

What makes the difference:

- Consistent, repeatable performance thanks to high-precision manufacturing and optimized preload

- Low wear and minimal maintenance due to premium materials, top-tier quality, and advanced lubrication

- Ideal for space-constrained applications with compact nut geometries for tight installation areas

- Tailored precision in accuracy classes from P1 to P5 and T5 to T10

- Reliable operation in tough conditions through special materials, custom lubrication, and application-specific design

Typical applications

Actuators in pick-and-place systems

Ball screws are essential in roboters and pick-and-place systems, where fast, precise motion is key. With minimal friction, zero backlash, and optimized geometry, they ensure smooth, controlled movements, even during rapid load changes and high-speed cycles.

Ultra-fine motion for sensitive operations

When processes demand motion at the millimeter or even micrometer level, ball screws deliver unmatched accuracy. They’re the ideal choice for delicate operations such as approaching fragile components, precision assembly, or controlled dosing in sensitive environments. With backlash-free operation, they ensure exact, repeatable movements even at very low speeds.

Linear axes in handling systems

In advanced handling and automation systems, ball screws drive the exact movement of linear axes. They offer pinpoint positioning, smooth feed motion, and reliable repeatability, all while meeting the demands of tight tolerances, dynamic motion, and fast cycle times.

Built for demanding environments:

- Clean room conditions and vacuum down to 10⁻⁷ torr

- Medical and lab-grade applications

- Food processing environments

- contaminated environments (particles from machining, processing fluids, etc.)

- highly corrosive environments (saltwater, chemicals, etc.)

- Aviation and space applications

- Temperatures down to -200°C or up to +250°C

... And much more.

The right solution for different automation systems

High-volume production

In fully automated and standardized production lines across industries like electronics, consumer goods, and automotive manufacturing, motion needs to be precise and repeatable — often hundreds of thousands of times a day. Steinmeyer ball screws deliver smooth, consistent feed motion, fast cycle times, and long-lasting precision. They’re ideal for tasks such as placing components on circuit boards, positioning workpiece carriers, or transporting pallets in linked production systems.

Custom automation solutions

In special-purpose machinery and flexible production cells, motion profiles are rarely standardized. They shift based on product type, format, or process and drive systems must adapt accordingly. Steinmeyer ball screws offer the versatility needed for these setups: from accurately positioning carriers during format changes to finely tuned feed motion in dispensing or bonding applications, or automatic adjustment of grippers and transport units in modular machine designs

Robotics

Collaborative, mobile, and humanoid robots work in sensitive and fast-paced environments, often right alongside people. This demands ball screws that are compact, lightweight, and capable of delivering smooth, precise movements with absolute repeatability. Steinmeyer ball screws provide the reliable, finely controlled motion needed for tasks like accurately positioning end-effectors, gently moving medical instruments, or powering motion in mobile service robots.

How small can ball screws be for automation?

Miniature ball screws with shaft diameters as small as 3 mm are perfect for tight spaces — without sacrificing precision or strength.

Are special materials available for cleanroom or hygienic environments?

Depending on the application, corrosion-resistant materials, food-grade lubricants, and many other options are available. Our experts are happy to help you select the perfect material combination for your needs.

What lubrication options are available?

Lubrication solutions vary by application and include manual lubrication or central lubrication systems. For some use cases, lifetime lubrication is even possible.

How fast can ball screws move in automated systems?

Speed depends on factors like pitch, diameter and installation. In most cases, high speeds and rapid acceleration are easily achievable.. We’d be happy to help figure out the best specs for your project.