January 17th, 2022

December 21st, 2021

Technical Information December 2021

New nut design in the Miniatur-Ball-Screw Range

Through Steinmeyer’s ongoing investments in continuous product improvements our Miniature Ball Screws with track-to-track ball returns now include new “PEEK” deflector systems.

Advantages:

- Significantly improved running properties

- Superior screw dynamics as the internal rolling elements (balls) motion more smoothly through their transitional ball paths / load zones

- With improved alignment and clean, well assured retention at assembly - the development of these next generation ball deflectors means the elimination of labor intensive hand finishing / tuning of the ball nut internals at assembly.

Details about the application and the designs can be found in our Technical Information in the download area.

Here you can get more information about our Miniature Ball Screws.

October 29th, 2021

Optimal Solution for the Medical Sector

The inherently smooth, precise and optimized running behaviors of our zero backlash ball screws have proven ideal for use in beam masking, biomechanics, and innovative pumps for respiratory and cardiovascular support systems.

Reliability testing, enhanced quality standards, materials traceability certs and supportive documentation for regulatory requirements can be provided.

Click here for more infomation about our Miniature Ball Screws

July 08th, 2021

New contact person for our International Sales

As of July 12nd, 2021, Alessandro Tettei will be at your disposal as Head of International Sales for your projects and inquiries.

We are looking forward to hearing from you.

April 28, 2021

You can make it to outer space.

And still stay firmly on the ground.

Special use for a Steinmeyer Ball Screw.

Ball Screws from Steinmeyer have flown in the Rosetta probe and were used to adjust the legs of Philae, the first space probe to land softly on a Comet.

- Update 12.01.2021

Ball screws for linear actuators

Find out more about our ball screws for linear actuators, electric cylinders, machine slides and motion platforms.

For linear applications we offer a wide range of ball screws, Ground ball screws and rolled ball screws.

They are the ideal link between motor and load for applications ranging from general industrial automation to high-precision tasks. The screws can be adapted to any bearing and drive configuration, including special ball returns with lead-diameter ratios of 1:1 or more.

Applications can be found in the following areas, for example:

Medical devices, laboratory equipment, pipetting, semiconductor technology, MEMS, scientific applications, assembly and packaging automation, printing machines, especially for high loads.

You can find detailed information in our brochure. Please click here to open.

September 15th, 2020

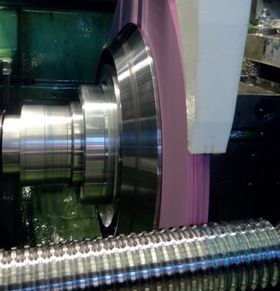

Improved running properties through optimized thread grinding process for Ball Screws

Within the scope of our further development and optimization of our ball screws, a new thread grinding process for the spindles of our ball screws has become established. This allows a smoother running of the nut to be achieved. Extensive tests have shown that the improved running characteristics have a positive effect on the life time and quality of the ball screws.

Further Information you can find in technology

100 years of Steinmeyer

2020 is a special year for August Steinmeyer - we look back on 100 years of tradition.

From spring onwards, the corona pandemic has affected our anniversary year and has influences the rhythm of the global economy dramatically.

We really hope that the situation will further calm down and that we will be able to continue our planning and celebrate our anniversary together with you soon. You and your families stay healthy!

Founded in 1920 by August Steinmeyer as “precision mechanics workshop”/”Feinmechanische Werkstätten”, Steinmeyer has established itself at its location in Albstadt to an international operating company over the past 100 years. With about 440 employees and focus on high-precision ball screws manufacturing, we have customers from various range of industries worldwide.

A short journey of our company’s history can be found in our history.

Optimised initial greasing through new lubricants and partial automation

As part of our product development and standardisation efforts, we have optimised our range of lubricants.

As of the second quarter, all ball screws will be lubricated at the factory with substances from the new lubricant portfolio. For even greater process reliability in initial greasing, we are focusing on partial automation. The users benefit from even greater operational reliability and longer component life.

Fit for the future - Newsletter 4, September 2019

Great progress in production - 80% of segmentation is implemented

About 80% of the modification of the facilities in Albstadt into a modern continuous production system have now been completed. The results are 50% shorter processing times and the inventories in prodction reduced to half.

Excellent top quality from German production

We were awarded by the "stern

August Steinmeyer GmbH & Co. KG is one of the few medium-sized companies to develop and manufacture its products entirely in Germany. The magazine "stern" has now honoured us with 172 other companies for this achievement. The award is the result of a study carried out by "stern", the Hamburg Institute of International Economics and the Institute for Management and Economic Research on the production sites of German companies.

New aerospace brochure

Our new aerospace brochure is available.

In the updated edition we inform you about the different applications of our Aerospace Ball Screws.

Fit for the future - Newsletter 3, March 2019

Further progress in production - The first machines have been relocated

In the first newsletter of this year you can find further information about the conversion of our production into flow production, and about Steinmeyer Mechatronik and our trade shows in 2019.

Guard Plus - Status monitoring of ball screws.

Together with ifm electronic, Steinmeyer has developed the technology concept Guard Plus in which sensors in the ball screw drive measure the preload and temperature directly at the rolling contact zone.

The evaluation electronics converts and analyzes the measuring signal and communicates with the machine control that has a light indicator and recommends an upcoming replacement of the ball screw. The measurement is even possible with superimposed or extraordinary operating forces. High cost savings are achieved by foreseeable service orders. A history record enables conclusions to be drawn about overloading the machine. In addition, the system helps to optimize the lubrication to the special requirements by application-specific load balancing.

Fit for the future - Newsletter 2, December 2018

Commissioning the heart of the system - Installation of our new oil system.

In the second newsletter you can find further information about our activities of our project “Segmentation”, and about the new location of our sales and customer service in North America.

Fit for the future - Newsletter 1, June 2018

Steinmeyer is setting a new course and investing in a new works structure. In the first Newsletter "Fit for the future" from August Steinmeyer you can find information about our comprehensive internal reorganization project “Segmentation”, new wiper systems and our upcoming fairs 2018.

Nearly four decades in the service of the firm

Steinmeyer recognizes Managing Directors Alexander and Joachim Beck in their retirement.

After nearly 40 years as managing partners of the Steinmeyer Group, Alexander and Joachim Beck were recognized in their well-deserved retirement. In their time as leaders of the company, they made important decisions for the future, including the acquisition of new companies and the enlargement of manufacturing capacity. Alexander and Joachim Beck will remain at Steinmeyer as board members. It was an emotional moment for all parties when the workforce of Steinmeyer sent off their longtime leaders with a standing ovation. The brothers lead the company over many decades. Steinmeyer was acquired by their father from the departed founder in 1940.

Steinmeyer supports the inclusive day care center LEO from Albstadt-Truchtelfingen. (Kopie 1)

Just a few days ago, Dr. Manfred Münch, Managing Director of Steinmeyer, made a donation of € 2,000 to the director of the day care center Mrs. Heidi Pokorny.

In their rooms, the children sang Christmas songs with Dr. Ing. Münch and accepted the donation with pleasure. "We are very pleased. This will allow us to buy more iPads, "says Ms. Pokorny. The electronic devices can be used for many purposes, especially helping disabled children participate in simple games. The integrative day-care center LEO is an institution with about 90 children, in which students with and without disabilities learn from each other and are also promoted together in small groups. True to the motto "Together and for each other", Steinmeyer GmbH is pleased to be able to realize joint projects with the Kita LEO in 2018 as well.

Steinmeyer, the leading ball screw manufacturer, has been supporting charitable organizations in the region for years with direct donations.

At Steinmeyer from Albstadt, three long-standing employees celebrated their company anniversary this year.

At a solemn ceremony, Dr. Manfred Münch, Managing Director of August Steinmeyer, congratulated the emloyees and presented certificates for their anniversaries.

For 25 years of service, Mr. Ali Ilhan and Mr. Rudolf Renner were honored. With the best wishes for the future, Rudolf Renner retired. For 40 years loyalty to the company, Mr. Bernd Danielzik received a certificate of honor from the Chamber of Industry and Commerce as well as a special award from the State Ministry of Baden-Württemberg. Dr. Münch thanked all the honorees for their excellent performance and loyalty as well as their contribution to the success of the company.

“DMG MORI PARTNER AWARD 2017” for August Steinmeyer

DMG MORI awarded August Steinmeyer for outstanding performance as top-supplier at the EMO 2017, the world`s leading trade fair for metal processing.

“Both digitization and automation are the central key elements of a future-oriented production. DMG MORI accelerate this change together with strong partners.” Underlined Christian Thönes, Chairman of the Executive Board of DMG MORI AKTIENGESELLSCHAFT, at the DMG MORI Partner Summit during the EMO 2017. The Specialists for development, production and application high precision Ball screws where awarded for reliable teamwork 2017 and outstanding cooperation with the “DMG MORI Partner Award 2017”.

The innovative strength as well as excellent performances and commitment of the Albstädter where decisive for this tribute. Owner Joachim Beck received the Award representative for August Steinmeyer.

Steinmeyer supports the inclusive day care center LEO from Albstadt-Truchtelfingen.

Just a few days ago, Dr. Manfred Münch, Managing Director of Steinmeyer, made a donation of € 2,000 to the director of the day care center Mrs. Heidi Pokorny.

In their rooms, the children sang Christmas songs with Dr. Ing. Münch and accepted the donation with pleasure. "We are very pleased. This will allow us to buy more iPads, "says Ms. Pokorny. The electronic devices can be used for many purposes, especially helping disabled children participate in simple games. The integrative day-care center LEO is an institution with about 90 children, in which students with and without disabilities learn from each other and are also promoted together in small groups. True to the motto "Together and for each other", Steinmeyer GmbH is pleased to be able to realize joint projects with the Kita LEO in 2018 as well.

Steinmeyer, the leading ball screw manufacturer, has been supporting charitable organizations in the region for years with direct donations.

Quiet running and measurably better!

Xi-Plus and optiSLITE-Technology. The ultimative in surface finish for running features.

Steinmeyer offers balls screws with optimized surface features for smooth running and low noise generation.

The Xi-Plus- and optiSLITE-Technology is available for precision and miniature ball screws and delivers excellent qualities.

The advantages are improved running characteristics, less vibrations, improved run-in, higher uniformity of ifling torque and high energy efficiency.

Please contact us to find the possibilities.

10 new trainees start in their working life.

Welcome in our team!

Starting with the new year of training we welcome 10 new trainees. 5 prospective industrial mechanics and 3 cutting machine operators, and as well an industrial business management assistant start their occupational career at Steinmeyer. We wish all of them a good start.

Since many years the traineeship at Steinmeyer is really popular. “We´re happy, that we can attend so many young people with their start in working life again”, says Marc Bitzer, trainer at Steinmeyer. The promotion of the young trainees is very important for us. This is shown in the quality of the apprenticeship. This year, the first cutting machine operator from Steinmeyer finished his apprenticeship with the grade “very good” and was taken in an unlimited employment contract.

Ultra Thrust Ball Screws

Specifically designed for very high loads. Ultra Thrust Ball Screws from Steinmeyer are not merely larger sizes of conventional ball crews. They have been specifically designed for the purpose of transmitting very high loads. The ball returns for example have been optimized for large ball sizes and for the specific use of such large screws. Also the robust nut body and the flange differ from conventional designs. Material selection and heat tratment take into account the special application requirements.

More details you can find in our brochure.

Download Leaflet Ultra Thrust Ball Screws