Lead Accuracy per DIN 69051 / ISO 3408

![[Translate to English:] Kontakt](/fileadmin/media/steinmeyer/kontakt.jpg)

Contact

Under +49(0)7431 1288-0 we are at your disposal.

Your desired size is not listed? We also manufacture individually. Give us a call!

Both DIN and ISO standards use the following terms and definitions to describe lead accuracy. The corresponding JIS designations are given in parentheses:

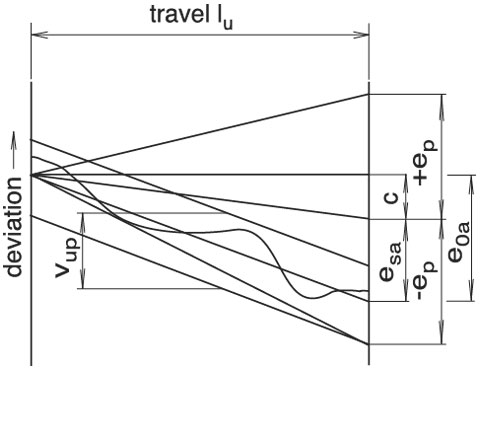

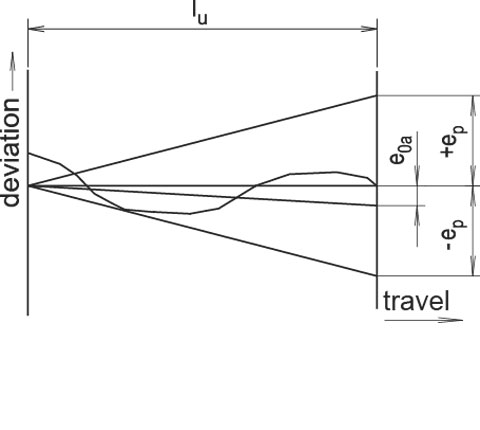

- Lead compensation c is used to compensate lead errors resulting from thermal growth or pre-tensioning of the ball screw shaft (JIS: T)

- The permissible lead deviation ep is an averaged lead error over the entire useful travel (JIS: E)

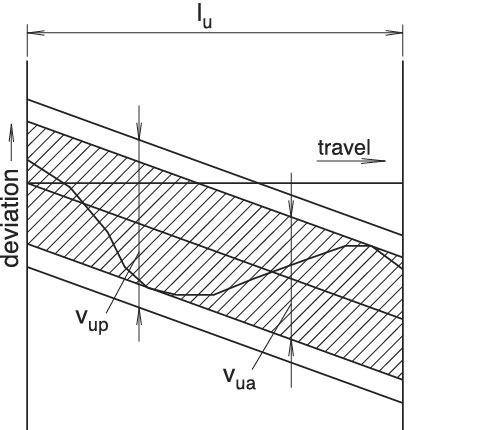

- The permissible lead fluctuation vup over the entire useful travel is defined as the vertical distance of two straight lines parallel to the line representing ep which enclose the entire lead error graph (JIS: e).

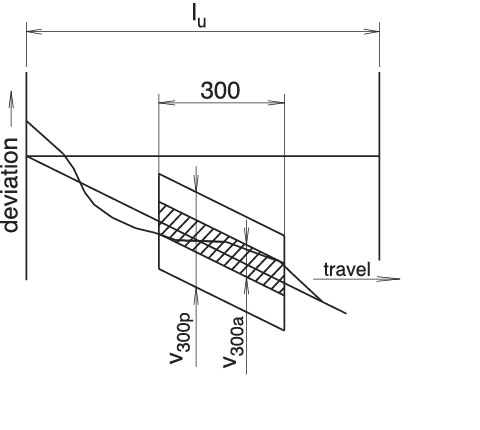

- The lead fluctuation v300p represents the same for any 300 mm interval (JIS: e300).

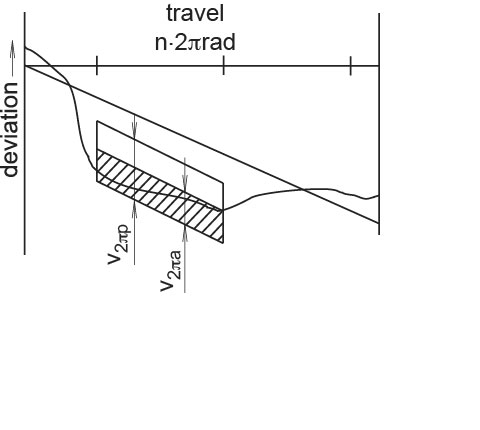

- And finally the lead wobble v2πp is the lead error within one revolution (JIS: e2π).

Tolerances of the DIN / ISO accuracy classes

- Overall lead error ep

- Lead fluctuation vup

- Lead fluctuation v300p

- Lead wobble v2πp

Technical Tip

Ball screws are normally categorized in accuracy classes, which not only define lead accuracy, but a number of different quality criteria like squareness and concentricity of mating surfaces, shaft straightness, friction torque fluctuation etc. Although this seems to be a trouble-free approach, ball screw users often choose to specify these other criteria by defining them in the source control drawing, while using ISO or DIN standard accuracy classes to only describe lead accuracy.

Steinmeyer uses accuracy classes 1, 3, 5, 7 and 10 per ISO / DIN standard. Accuracy classes 0, 2 and 4 are not contained in these standards, but have been added to match the JIS 1902 standard.