Variation Of Friction Torque

![[Translate to English:] Kontakt](/fileadmin/media/steinmeyer/kontakt.jpg)

Contact

Under +49(0)7431 1288-0 we are at your disposal.

Your desired size is not listed? We also manufacture individually. Give us a call!

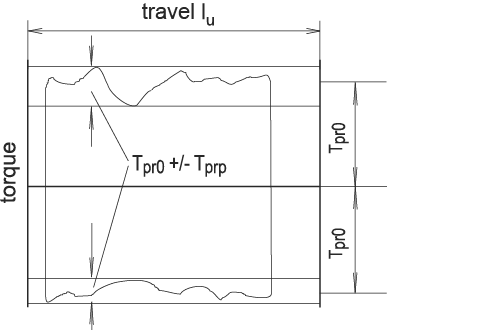

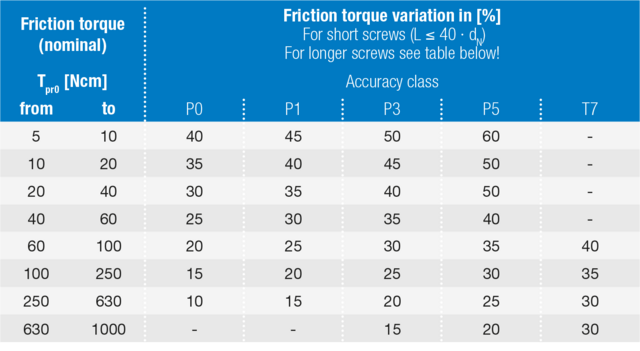

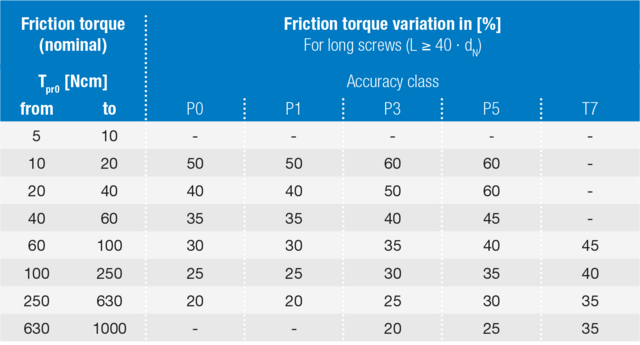

The friction torque tolerance is solely defined for preloaded ball screws with double nuts and is mainly affected by the accuracy class, preload value and diameter/length ratio of a ball screw. The permissible torque fluctuation is given in % based on the nominal idling torque of a preloaded ball screw.

The values of the interclasses can be determined by interpolating.

Technical Tip

Steinmeyer can provide a friction torque chart for preloaded ball screws upon request (for an extra charge!). The test method described in the ISO / DIN standard is to run the ball screw, with a thin film of oil, at 100 rpm and without wipers. Other test methods can be agreed upon. The values shown here apply to the test method per ISO / DIN standard.

Tolerances for the friction torque of preloaded single nuts are specified individually.

Aerospace ball screws are often tested for idling torque, although they are normally not preloaded. This test serves to determine proper operation of wipers and seals. This test can be part of the ATP; it is normally done with the ball nut greased and ready for shipment.