Bearing Journals and Shaft Pre-Tensioning

![[Translate to English:] Kontakt](/fileadmin/media/steinmeyer/kontakt.jpg)

Contact

Under +49(0)7431 1288-0 we are at your disposal.

Your desired size is not listed? We also manufacture individually. Give us a call!

Support bearings facilitate rotation of the shaft while transmitting axial loads from the ball screw into the surrounding structure. They have to do that with minimum friction and the smallest possible deformation under changing loads. Modern ball screws have high load capacity and rigidity, which places high demands on bearings as well. Only high-end bearings which have been designed specifically for use with ball screws can match the load capacity and rigidity numbers. Using inferior bearings yields unsatisfactory results. It is also important that the interface between ball screw and support bearings is designed properly.

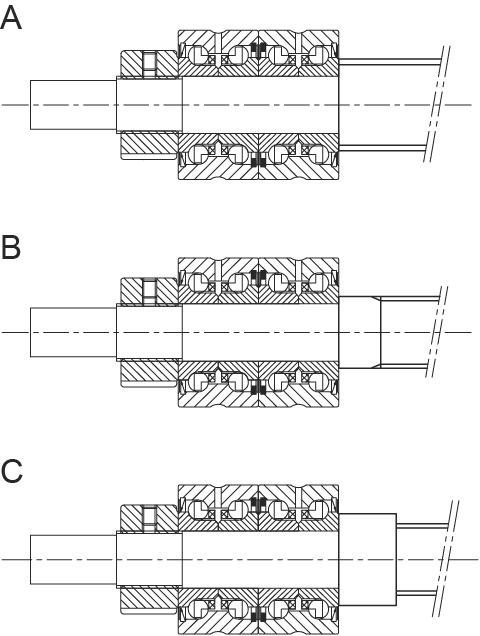

- A: The simplest journal design is a bearing seat that is small compared to the root diameter of the ball thread. If the shoulder surface between the bearing journal diameter and the root diameter (= nominal diameter - ball diameter) of the ball thread is sufficient to support the bearing preload plus the maximum thrust with reasonable surface pressure, then this cost-effective solution is recommended.

- B: Should the shoulder surface be too small, then the shaft could actually bend when the locknut is tightened to preload the bearings. In this case, a full shoulder is needed, that is the ball thread has to be incomplete instead of cutting through the shoulder - sometimes referred to as a "dead start thread". This is possible for ground and whirled screws, but impossible for rolled screws. Make sure that the other end of the ball thread is complete to allow mounting of the nut. Two incomplete ends of the ball thread means costly complications of nut mounting!

- C: If the shoulder surface is still insufficient, then a collar becomes necessary. Collars can be heat shrunk onto the ball screw if there is still some difference between bearing bore diameter and screw O.D. Shrunk collars are also possible for rolled screws. If there is not enough shoulder for the shrunk collar to prevent axial slippage, then the collar has to be solid, which means considerable machining time. This is the most expensive solution.

Technical Tip

If a long screw is to be pre-tensioned to compensate for thermal expansion, thrust bearings are required at both ends. One of them needs to be adjustable to set exact tension of the shaft. A way to do that is by using a second locknut thread. Other possibilities include shims to set pre-tension. Always make sure to check elongation of the screw with a dial gage while tensioning it.

Sufficient shoulder area is important, since creeping of the metal and loss of bearing preload results from excessive surface loading. If the shoulder surface is not symmetric (for example when the thread cuts through it and the shoulder surface below the root is insufficient to support the bearing), then cocking of the bearing will cause bending of the shaft with unsatisfactory runout of the ball screw.