Guard Plus Technology

![[Translate to English:] Kontakt](/fileadmin/media/steinmeyer/kontakt.jpg)

Contact

Under +49(0)7431 1288-0 we are at your disposal.

Your desired size is not listed? We also manufacture individually. Give us a call!

Status Monitoring of Ball Screws

Benefits

- Maintenance can be anticipated and planned

- Maintenance costs are reduced

- Overload detection

- Lower cost of ownership

Application:

Machine Tools Industry

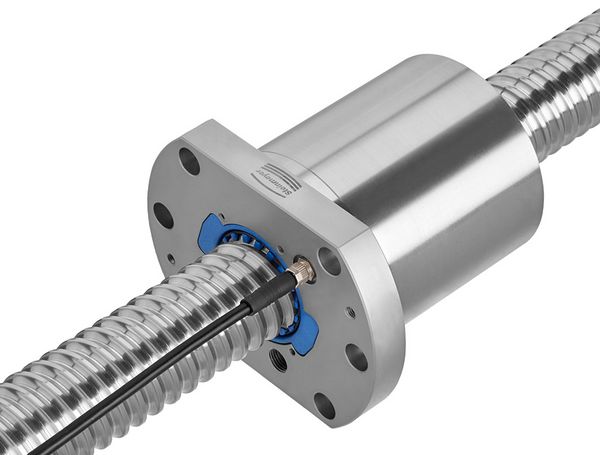

Guard Plus Ball Screw with Sensor.

Maintenance can now be anticipated and planned.

Preventative maintenance of machinery and plants on the basis of real-time data is an important new trend. Sensors detect wear of critical machine components and transmit data to software which optimizes the maintenance plan and reduces unplanned downtime.

Automated data detection.

The new sensor technology Guard Plus is used to optimize machine maintenance and to minimize unplanned downtimes. The key benefit of this solution is the automated data detection which allows accurately timed maintenance. Problems can thus be detected at an early stage and necessary maintenance can be taken in time.