Rigidity (Stiffness)

![[Translate to English:] Kontakt](/fileadmin/media/steinmeyer/kontakt.jpg)

Contact

Under +49(0)7431 1288-0 we are at your disposal.

Your desired size is not listed? We also manufacture individually. Give us a call!

The rigidity of a ball screw not only has a strong impact on positioning accuracy, but also plays an important role concerning the dynamic behavior of a linear drive. The importance to the latter is normally underestimated.

- Rigidity according to ISO 3408 or DIN 69051 is a value labeled Rb/t. This value is obtained from theoretical elastic deformations obtained from the theory of Hertzian pressure with the variables of track conformity, contact angle and the number of load carrying balls. Rb/t is a relatively high number.

- When the deformation of the nut body (diameter widening, longitudinal expansion) is included, the value is labeled Rnu and is already significantly lower thanRb/t.

- To obtain a real value, the theoretical vaule of Rnu has to be corrected further, since not all balls carry the same load. Depending on the accuracy grade of the ball screw, the correction factor varies. The reduced value, which is closer to reality and measurable, is designated Rnu,ar

Steinmeyer publishes only Rnu,ar values in our catalog and on our website. Please be sure to compare these values only to similarly defined rigidities from other manufacturers, and also ensure that the comparison is based on the same preload value you want to use (see right column regarding the impact of preload on rigidity).

Technical Tip

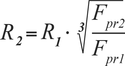

Higher preload results in increased rigidity. But rigidity increases only with the cubic root of preload. To compare stiffnesses based on different preload settings, multiply rigidity values by the cubic root of the ratio of the preloads. For example:

where R1 and R2 where Fpr1 and Fpr2 are the corresponding rigidities.