Critical Speed

![[Translate to English:] Kontakt](/fileadmin/media/steinmeyer/kontakt.jpg)

Contact

Under +49(0)7431 1288-0 we are at your disposal.

Your desired size is not listed? We also manufacture individually. Give us a call!

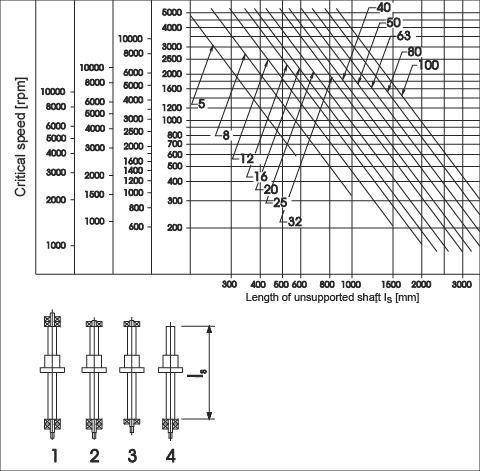

Similar to buckling, critical speed depends on the support bearing configuration. Fixed support bearings are assumed to resist angular deflection of the shaft, while simple support bearings do not. A bearing assembly consisting of two simple bearings with a spacer would however qualify as "fixed" bearing for the purpose here.

For long screws, we recommend using the following equation. Make sure to select the proper factor for the bearing configuration used:

nk Critical speed [rpm]

dN NNominal diameter [mm]

ls Unsupported length [mm]

k Support bearing factor

fixed - fixed: 25,5 (1)

fixed - supported: 17,7 (2)

supported - supported: 11,5 (3)

fixed - free: 3,9 (4)

Technical Tip

Critical speed is the first resonant frequency (speed) of the rotating shaft. Resonance in a rotating shaft can be catastrophic and even break the shaft. However, not all ball screws will necessarily exhibit such behavior since the nut represents another support of the shaft, permanently changing the unsupported length of the shaft and its resonant frequency. Nevertheless Steinmeyer recommends operating a ball screw only up to a maximum speed not to exceed approximately 80% of the critical speed, or to discuss the possibility of higher speed with our engineers.

For ball screws with rotating nuts, critical speed may be exceeded if the run-out of the rotating nut is kept within tight tolerances. A perfectly concentric nut will not "pump" critical amounts of energy into the shaft even if it is at or near its critical speed.

Pre-tensioning and critical speed

Contrary to general belief, pre-tensioning the ball screw shaft does not change the critical frequency of the shaft. It is the stiffness against bending that resists centrifugal forces in a rotating shaft, not tension.