Accounting for Preload in the Life Calculation

![[Translate to English:] Kontakt](/fileadmin/media/steinmeyer/kontakt.jpg)

Contact

Under +49(0)7431 1288-0 we are at your disposal.

Your desired size is not listed? We also manufacture individually. Give us a call!

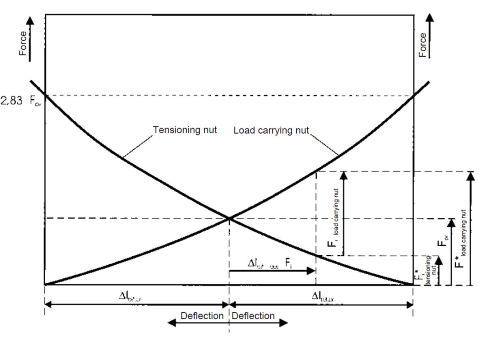

In this step, we modify axial forces to reflect the impact of preload. The preload graph shows how internal forces in the ball nut are affected by external forces and preload.

The preload graph includes two lines which represent the forces and resulting deformation for both nut halves in a double (or pitch shift) nut. The center of the chart, where the two lines cross, shows the situation of the nut with no external forces. Both nut halves carry the same load - which is the preload Fpr.

If an external force is added, then the load in one nut increases, while it decreases in the other. The resulting difference of the two forces is equal to the external load.

The load in each nut can be read from the two lines and this load is to be used for life calculations. As a simple approximation, the nut with the higher load has to carry the preload plus approximately half of the external load. Using this approximation for Fi* is accurate enough.

Technical Tip

As a quick and simple approximation for the internal load in nuts with 2-point contact, just add or subtract half of the external thrust Fi to or from the preload Fpr. Whether you call a certain thrust direction positive or negative does not matter. But you have to keep this direction orientation the same for the whole duty cycle. The nut with the highest load then determines service life.

When calculating modified loads for nuts with 4-point contact, all external thrust has to be added regardless of load direction. The factor of 1.25 (5/4) is necessary to account for the fact that the balls have 4 contact points, causing fatigue much sooner than in a nut with 2 contact points. This approximation is accurate enough in cases with normal loads and duty cycle.