Rotational Speed Limits

![[Translate to English:] Kontakt](/fileadmin/media/steinmeyer/kontakt.jpg)

Contact

Under +49(0)7431 1288-0 we are at your disposal.

Your desired size is not listed? We also manufacture individually. Give us a call!

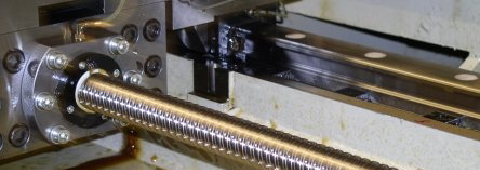

Critical speed

Critical speed is the lowest rotational speed at which the ball screw shaft is in resonance. In applications with rotating shafts it limits the RPM of the screw. Variables that influence critical speed are shaft diameter, unsupported length, and configuration of support bearings.

Maximum Speed

A second limitation derives from inertial forces on the balls. It depends on the internal construction of the ball nut (in particular the ball return) and the ball size.

continue

DN value

The concept of DN is a simplified way of determining the maximum rotational speed of a ball screw. DN is simply the multiplication of nominal diameter of the ball screw in mm times the maximum allowable speed in rpm. Keep in mind that for very small and very large screws this will not return valid numbers.

Technical Tip

The maximum nut speed should not be exceeded under any circumstances. There are, however, special executions available that are suitable for higher speeds, so please inquire.

Critical speed may be exceeded in certain cases - contact our application engineers for further advice. And critical speed is not a significant limitation in applications with rotating nuts.

When operating at prolonged high speeds, heating of the ball screw may become the limiting factor. Hollow screws for internal cooling are available, but this requires an expensive additional system with its often troublesome rotating unions. Another approach is to add a cooling jacket to the nut, which prevents heat migration into the slide.

Another possible solution to running at high speeds for prolonged time is Steinmeyer's ETA+ technology. This advanced ball screw design produces less than half the heat compared to a regular ball screw of same size. So steady-state temperatures remain much lower. This may eliminate the need to use a forced cooling system for the ball screw shaft. Pre-tensioning amounts to compensate for thermal expansion are lower too, significantly reducing the burden on the support bearings from tension forces.