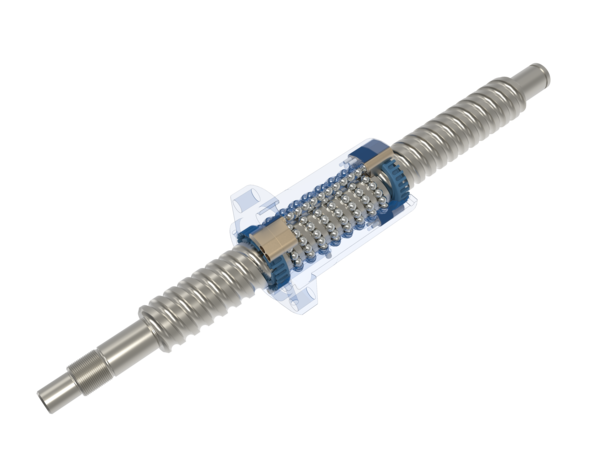

Precision, speed, and repeatability — that’s what modern machine tools are built on. And at the center of it all: ball screws. They transform motion into accuracy, making complex movements controllable, reliable, and efficient.

From high-speed machining centers to ultra-precise grinding machines and automated tool changers, Steinmeyer ball screws deliver performance you can count on, even under demanding conditions like heavy loads, vibrations, or shifting temperatures.

Every application is unique. Whether you're designing a compact linear module or a large gantry system, the drive solution should fit the machine, not the other way around. With a wide variety of sizes, leads, preloads, and nut designs, Steinmeyer enables tailored engineering for maximum performance and service life.

Working closely with machine builders, Steinmeyer develops drive solutions that combine power, precision, and long-term efficiency. Built to meet your goals, and made to last.

Let's talk about your project!

Use Cases

Linear motion axes

Ball screws deliver precise, smooth linear movement for machine parts along all axes. They ensure accurate positioning, consistent feed rates, and repeatable results, making them the vital component in many machining processes.

Fine adjustment and calibration

When movements require micrometer-level precision—such as positioning workpiece holders, sensors, or other delicate components—ball screws deliver the accuracy and fine control needed. Their backlash-free design ensures precise, consistent adjustments every time.

Automation and support functions

Ball screws are ideal for driving auxiliary functions within machines. From moving secondary axes to clamping or swapping components, they deliver reliable performance in automated processes that operate nonstop.

Why choose Steinmeyer ball screws

Steinmeyer ball screws ensure smooth, prcise and reliable motion in machine tools. Engineered for long-term performance, even under dynamic loads, they provide precise axis movement, stable feed rates and repeatable results.

What makes the difference:

- Exceptional positioning accuracy, made possible by precisely ground shafts (available from accuracy class P1)

- Ultra-smooth motion with minimal torque inconsistency and optimized raceway geometry

- Low wear and reduced maintenance due to premium materials, precision manufacturing, and optimized lubrication

- Thermal stability supported by optional cooling systems for both screw and nut

- Even, precise movement at low feed rates, enabled by consistent friction levels and optimized geometry

- Excellent stiffness through application-specific nut designs and carefully selected preload levels

- High-dynamic versions for fast axis movement with maximum acceleration and speed

Specialized wipers tailored to each application's demands

For especially challenging tasks, including those found in special-purpose machinery, Steinmeyer also offers advanced technical solutions such as:

Heavy-duty ball screws Rotating nuts Cooled ball screws Differential roller screws

ETA+ Technology - Ahead by design

In grinding and other ultra-precise machining tasks, even the smallest motion error can impact the final quality. That’s where Steinmeyer’s ETA+ technology makes all the difference. Developed in-house and unmatched on the market, ETA+ sets the standard for smooth, reliable ball screw performance. The technology is ideal for both high-precision applications like grinding machines and for highly dynamic systems with long travel distances, high speeds, or even oscillating motion.

By optimizing technology, ETA+ minimizes friction and vibration to a minimum, resulting in measurable performance for demanding machine tool applications:

Up to 50% reduced energy loss

Significantly lower heat generation during operation

Noticeably longer service life

Quieter running behaviour

Exceptionally smooth and consistent motion

ETA+ isn’t just theory — it’s a proven technology that has been trusted for decades in demanding machine tool applications. Its unique design continues to outperform competitors, delivering measurable benefits wherever precision and efficiency really matter.

The perfect ball screw for every machine tool

Grinding machines

Precision grinding demands smooth, consistent feeds and pinpoint accuracy. Steinmeyer ball screw, especially those featuring ETA+ technology, provide exceptional smooth motion, low friction and thereby impeccable surface quality.

Milling and turning machines

Steinmeyer ball screws excel in milling and turning applications, providing the stiffness and repeatability needed for dynamic positioning. They enable fast, precise axis movements and reliable process control, even under varying loads.

Other machine tools

Steinmeyer ball screws also bring dependable, precise motion to less conventional machining methods like EDM, honing, and metrology. For specialized requirements, we offer customized options such as heavy-duty versions, special nut designs, and unique materials tailored for custom or special-purpose machines.

How long do ball screws last in machine tool applications?

With proper design, lubrication, and environmental conditions, our ball screws can operate reliably for thousands of hours. We’ll support you early in the design phase with lifetime calculations, lubrication and geometry recommendations and technical guidance to help you get the most out of your machine.

Which accuracy classes are suitable for machine tools?

For main axes, we typically recommend accuracy classes P3 to P1, depending on your requirements for positioning precision and repeatability. For secondary axes or less demanding applications, classes like P5, T5, or T7 may be sufficient. Our technical team is happy to help you finding the right choice for your application.

What sets ETA+ apart from standard ball screws?

ETA+ is Steinmeyer’s proprietary technology, engineered for applications where motion quality and efficiency are critical. Its unique preload design minimizes friction and delivers smoother motion, lower heat generation, quieter operation, and significantly longer service life. Applications like grinding, where precision is everything, benefit especially from ETA+.

Which nut styles are available for machine tools?

Flanged nuts are commonly used in machine tools due to their simple mounting options. That said, we offer a wide range of nut styles to suit different needs, including single or double nuts, various return systems, and wiper configurations. Our expertswill help you choose the best solution for your application.

Are there ball screws with integrated cooling?

For heat-sensitive applications or processes that generate significant heat, Steinmeyer offers cooling options for both the screw and the nut.

How frequently should a ball screw be lubricated?

Ball screw nuts for machine tool applications typically include lubrication ports for easy connection to centralized lubrication systems. Manual or application-specific lubrication solutions can also be implemented as needed.

What is the maximum operating speed of a ball screw?

Maximum speeds and feed rates depend on multiple geometric and technical parameters. We’ll work with you on request during the design stage to define the right motion parameters and estimate the expected lifetime of your setup.

Can ball screws be used in vertical axes?

Steinmeyer ball screws are well-suited and reliable for vertical axis applications. Depending on the load and application, adjusting parameters like lead or preload may be recommended — and we’ll guide you through those decisions.