Driving innovation in medicine and research

When health and life itself is on the line, there’s no room for compromise. In medical and life science applications, absolute precision isn’t just important but critical.

From the steady precision of robotic-assisted surgery to the delicate control of diagnostic instruments, Steinmeyer ball screws are at the heart of technologies that care for, heal, and protect patients. Every movement matters. That’s why the drive systems are engineered to meet the highest demands. They are compact, quiet, durable, and highly reliable, tailored to specific use cases and seamlessly integrated into complex systems. Even under challenging conditions, our components deliver consistent performance and long-term reliability.

But precision alone isn’t enough. In environments where every detail counts, engineering excellence is combined with a deep understanding of regulatory standards, documentation requirements, and the responsibility that comes with shaping technologies that directly impact human lives. From groundbreaking research to life-saving treatment— Steinmeyer motion solutions move what matters most.

Start your medical project today.

The perfect solution for every life science technology

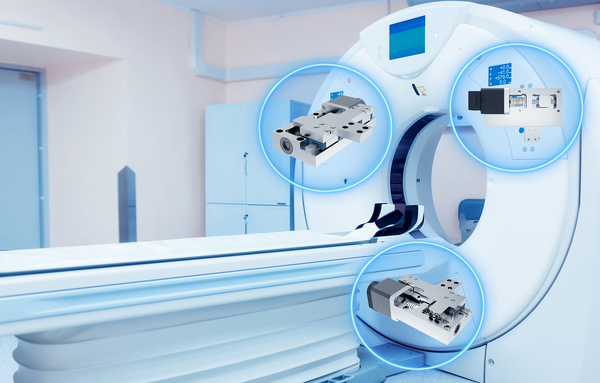

Imaging and diagnostics

Ball screws provide precise and consistent positioning in MRI, CT, and other imaging systems. This helps deliver reliable diagnoses while reducing radiation exposure for patients.

Therapy, rehabilitation, and prosthetics

Ball screws deliver smooth, dependable motion in therapy devices like ventilators and support natural movement in orthotics, prosthetics, exoskeletons, and rehabilitation equipment—helping patients regain mobility and improve their quality of life.

Surgical systems

Compact ball screws enable delicate movement in surgical robots, radiation therapy machines and minimally invasive instruments - ensuring control and safety for gentle procedures.

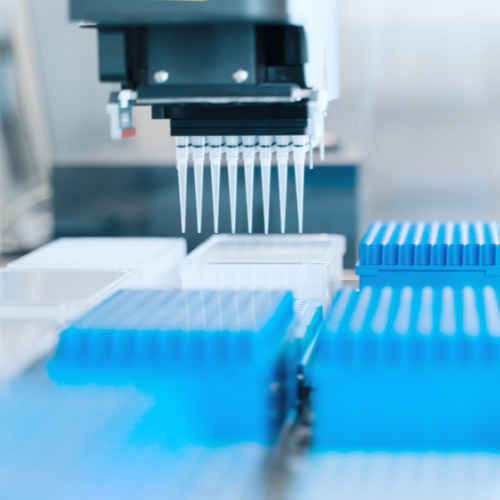

Biotechnology and pharmaceuticals

Precise positioning and dosing are essential in pharmaceutical manufacturing and biological sample handling. Customized ball screws provide the reliability and repeatability required for these critical processes.

Laboratory automation

Automated pipetting robots, liquid handling devices, and analyzers rely on durable, high-precision drives to keep processes fast and accurate, even during continuous operation.

Medical research and development

From early prototypes to full production, ball screws offer reliable, repeatable motion to support a wide range of innovations in medical and life science research.

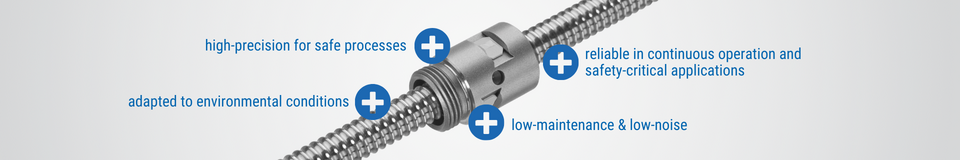

Why choose Steinmeyer ball screws

In medical technology, every detail counts—whether it’s making an accurate diagnosis, ensuring a procedure’s success, or keeping patients safe. Steinmeyer ball screws are designed to meet these high standards and have been trusted for decades in sensitive life science applications.

What makes the difference:

- Outstanding precision and repeatability for smooth, consistent motion and reliable processes

- Dependable performance even during long-term use and in critical applications

- Low-maintenance design with carefully selected materials and lubrication

- Compact size that fits perfectly into complex, space-tight systems

- Quiet operation, ideal for environments close to patients

- Adaptable to cleanroom conditions and other special environments as needed

Custom-engineered ball screw drives for your application:

Learn how precisely engineered calculation methods, optimized materials, functional coatings, and tailored lubricants sustainably increase the reliability, service life, and process safety of medical engineering systems.

Technical consulting Request a project Calculate service life Medical engineering lubricants

Case study: Aperture control in CT Scanners

Driven by Steinmeyer ball screws

In the world of medical diagnostics, every tiny aspect holds the power to change lives. Achieving sharp, clear images in radiology relies not only on advanced sensors but also on precise motion control working flawlessly behind the scenes.

The aperture adjustment of the computed tomography systems is realized by a specially developed assembly from Steinmeyer Mechatronik. At its heart is a highly precise ball screw that carefully adjusts the tungsten apertures as the X-ray source rotates around the patient. This exact control focuses the X-ray beam on the necessary area, producing exceptionally detailed, low-noise images while minimizing radiation exposure. The result is safer scans and more accurate diagnoses.

The technical challenge is significant. The assembly continuously rotates around the patient. Because of the large rotation diameter, strong lateral forces act on the system, putting significant stress on its components. However, thanks to the precision manufacturing of the ball screw and a robust design, the movement remains accurate and repeatable—even under these demanding conditions. The system performs reliably with minimal risk of error.

Currently used in devices from a leading global manufacturer, this aperture control assembly guarantees unmatched precision and reliability. It ensures consistent, accurate positioning doctors can trust—and patients can depend on.

Learn more about the single cylinder nut Request a comparable application

Case Study - Aperture actuator for computed tomography systems

- Peak speeds up to 50 mm/s enable ultra-fast imaging - reducing radiation exposure by up to 80%

- Cylindrical single nut, series 1214

- 4-point contact and single-start

- Long-term lubrication

- Stability in high-acceleration environments

- Repeatability up to 1.4 µm ensures high-resolution, low-noise images

- Reduced noise levels at high rotational speeds

- Cost-optimized design without compromising performance

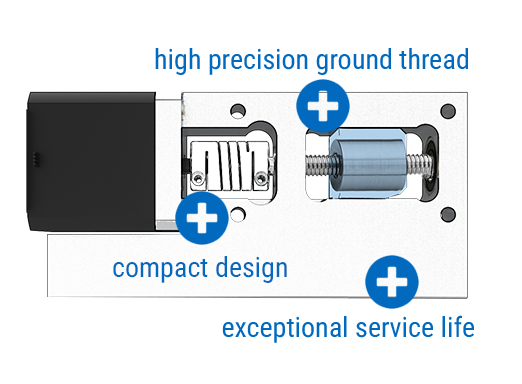

Case Study: Drive solutions for ventilators

In critical care, ventilators are often the last line of defense, working around the clock to support or even replace a patient’s breathing. Whether used for a few hours or over many days, these systems must perform with absolute reliability. At their core are motion components that manage valves, pistons, and pressure controls with incredible precision. This fine-tuned motion ensures safe and consistent airflow, directly impacting both patient safety and comfort.

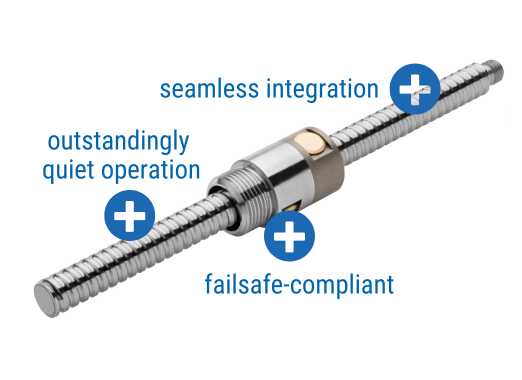

Ball screws play a key role in making that possible. Steinmeyer’s solutions are used by leading medical device manufacturers around the world. Engineered for demanding conditions, they deliver long-lasting performance with minimal maintenance - an essential quality for equipment that simply can’t fail. Thanks to their compact design and low weight, these ball screws are easy to integrate into a variety of ventilator architectures. Their quiet, low-vibration operation is especially valuable in intensive care units, where patients need rest and equipment must function smoothly and silently, often for extended periods.

By offering custom-engineered solutions, Steinmeyer supports the development of next-generation ventilator systems, ensuring dependable respiratory support when it matters most.

Learn more about the mounting thread nut Request a comparable application

Case Study - Drive solution for ventilators

- Connection thread nut, series 1112

- Optimized thread grinding process

- High load capacity in a miniaturized design with low weight

- Adaptable to various motor types

- High system compatibility for existing architectures

- Outstanding quiet operation

- Maintenance-free with exceptionally long service life

- Failsafe-compliant for use in intensive care units

Miniature ball screws – tailored to the application

The following miniature ball screws can be flexibly adapted to a wide range of requirements. Through individual design and custom development, solutions are created that are precisely tailored to your application.

Flange single nut

Flange nuts offer a rigid and installation-friendly mounting solution for demanding linear motion applications.

Integrated flange provides a precise, defined mounting interface

High system stiffness through optimized load distribution

Quick, repeatable installation ideal for series production and assembly efficiency

Are ball screws suitable for continuous operation in medical environments?

Yes. Steinmeyer ball screws can be designed specifically for long-term use under continuous load. Special lubrication concepts, carefully selected materials, and precision manufacturing ensure consistent performance and high reliability, even under demanding conditions.

How loud are ball screws during operation?

Thanks to optimized raceway geometry and precise manufacturing, Steinmeyer ball screws operate with minimal noise and vibration. This is especially important in environments close to patients or in sensitive laboratory settings.

Does Steinmeyer support medical device certification processes?

Steinmeyer has many years of experience working with medical device manufacturers and is highly familiar with the regulatory landscape. Support includes documentation, traceability, and component design aligned with the customer’s approval strategy. Production is certified according to ISO 9001.

Can Steinmeyer ball screws be sterilized?

In many medical applications, ball screws are integrated in such a way that they do not come into contact with sterile zones, making direct sterilization unnecessary. When sterilization is required, Steinmeyer provides guidance on suitable materials and configurations that are compatible with common sterilization methods.

![[Translate to English:] Kugelgewindetrieb 1112 Anschlussgewindemutter [Translate to English:] Kugelgewindetrieb mit Anschlussgewinde Einzel Mutter mit 4-Punkt Kontakt und Einzelgang Umlenkung](/fileadmin/_processed_/8/9/csm_mkgt-1112-1132_Ball-screw_Kugelgewindetrieb_kgt_Anschlussgewinde-Einzelmutter_Kugelgewinde_a9fabb444d.jpg)

![[Translate to English:] Kugelgewindetrieb 1214 Zylindermutter [Translate to English:] Zylinder Einzel Mutter mit 4-Punkt Kontakt und Einzelgang Umlenkung](/fileadmin/_processed_/1/c/csm_mkgt-1214-1234_Ball-screw_Kugelgewindetrieb_kgt_Einzelgangumlenkung_kugelgewindemutter_Zylinder-Mutter_a286f7d999.jpg)

![[Translate to English:] Kugelgewindetrieb 1412 Flanschmutter [Translate to English:] Flansch Einzel Mutter mit 4-Punkt Kontakt und Einzelgang Umlenkung mit Standard Abstreifer](/fileadmin/_processed_/e/8/csm_mkgt-1412-1432_Ball-screw_Kugelgewindetrieb_kgt_Kugelgewindespindel_Flansch-Einzelmutter_eb8a18ec9d.jpg)

![[Translate to English:] Kugelgewindetriebe 1510 Federverspannte Anschlussgewindemutter [Translate to English:] Federverspannte Anschluss Gewinde Doppelmutter mit 2-Punkt Kontakt und Einzelgang Umlenkung](/fileadmin/_processed_/a/e/csm_mkgt-1510-1530_Ball-screw_Kugelgewindetrieb_kgt_Kugelgewindespindel_Anschlussgewinde_Doppelmutter_916fa3da3a.jpg)