Powering the next generation of robotics

Robots that walk like humans, grasp, feel, and carry must combine power with sensitivity. Modern robotics is rapidly advancing toward natural, intelligent movement. Whether it's humanoid robots with complex joints, dog-like walking robots for rough terrain, supportive exoskeletons worn on the body, or autonomous service robots interacting directly with people, they all place the highest demands on drive technology.

In these systems, every movement influences function, safety, and human interaction. Steinmeyer ball screws deliver the required precision and dynamics in an ultra-compact design. They enable lifelike arm, leg, and finger movements in humanoid robots, ensure stable walking and wheeled mobility, support smooth joint articulation in exoskeletons, and power quiet, reliable functions in intelligent assistance systems.

Wherever robots move closer to humans — physically or functionally — drive technology must rise to meet the challenge. With Steinmeyer, it does.

Let's talk about your project!

The right solution for any robot

Humanoid robots

Ball screws are at the heart of movement in humanoid robots, powering everything from fingers and hands to legs and joints. They handle a huge range of motions, whether it’s gently picking up a fragile object or firmly tightening a screw. Compact, precise, and adaptable, they deliver smooth, lifelike movements that are both sensitive and strong.

Service robots

Service robots work alongside people every day: in public spaces, hospitals, care facilities or even at home. Ball screws help them perform quiet, accurate motions like opening a medicine compartment or serving food. Steinmeyer provides the perfect components to make technology that supports without getting in the way.

Exoskeletons

Exoskeletons bring humans and machines together in close cooperation. Ball screws enable smooth, controlled movements for walking, lifting, or supporting. Thanks to their compact size and precise control, they’re the ideal choice for wearable systems used in industry, therapy, and rehabilitation.

Case Study: Artificial finger joints - barely different from a human hand

Compact ball screws are essential to creating smooth, natural hand movements in humanoid robots. Depending on the mechanical design, miniature ball screws as small as 3 mm in diameter are used in various configurations. With lead pitches starting at 0.5 mm, they perfectly balance strength, precision, and sensitive responsiveness.

A sucess story showing, how technology comes to life:

Steinmeyer Mechatronik developed a fully integrated assembly for an artificial finger joint on behalf of a leading prosthetics manufacturer. This tiny mechanism is the heart of a modern hand prosthesis, small enough to fit seamlessly into the hand’s overall design, yet strong enough to perform everyday tasks effortlessly.

At the core of these movements are ball screws specially engineered by Steinmeyer. Designed for compactness and exceptional sensitivity, they replicate complex joint motions with astonishing realism — almost indistinguishable from a natural hand.

For individuals who have lost part of their hands through amputation, this innovation transforms everyday life. Simple actions like opening a bottle, fastening a zipper, or holding a child’s hand become possible once again. Where there was dependence, independence now takes hold — restoring movements that once felt out of reach.

This remarkable precision in mimicking human movement is not only a milestone for advanced prosthetics but also a beacon for humanoid robotics. Genuine interaction in these applications require the same blend of subtlety and strength.

Steinmeyer Mechatronik and Steinmeyer showcase how advanced drive technology enables natural movement — giving machines a human touch.

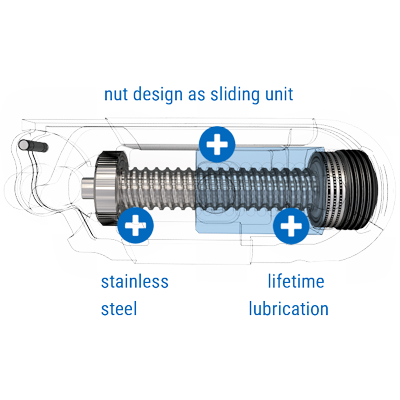

Case Study - "Finger Joint"

- Applications prosthetics, humanoid robots

- Maintenance free

- Efficient design

- Smooth motion

- Adaption to special environmental conditions

- Stainless steel, lifetime lubrication

FAQ - Steinmeyer Ball Screws in robotics

Are Steinmeyer components suitable for use in humid or contaminated environments (e.g., in household or industrial robots)?

Depending on the operating conditions, Steinmeyer ball screws can be adapted with special wipers, corrosion-resistant materials and suitable lubricants. This makes them ideal for environments involving moisture, dust, or other contaminants. They're also well-suited for systems that require regular cleaning with water or chemicals, such as in food processing or medical robotics.

What safety considerations are addressed for applications near humans, such as service robots?

When machines operate in close proximity to people, safety is essential. Steinmeyer solutions support smooth, controlled motion with high repeatability—enabling systems that interact with humans reliably, gently, and safely.

Can Steinmeyer deliver complete mechanical assemblies?

Absolutely. Companies within the Steinmeyer Group design and manufacture fully integrated, ready-to-install assemblies—combining mechanical components, drive systems, and optional sensors or electronics. Customers benefit from fewer interfaces, high integration, and thoroughly tested quality—from prototypes to full-scale production.

Are there special ball screws designed for humanoid robotics?

Our compact miniature ball screws, starting at just 3 mm in diameter with fine leads, are ideally suited for precise, powerful movements in artificial joints. They enable natural, human-like motion—especially in areas with limited space, such as robotic hands or arms.