Semiconductor manufacturing demands the highest levels of precision, process reliability, and contamination control.

Whether it’s wafer handling, lithography, or advanced inspection systems, every application pushes motion components to their limits: extreme accuracy, vacuum compatibility, and ultra-low particle emissions, sometimes even requiring the complete exclusion of certain materials.

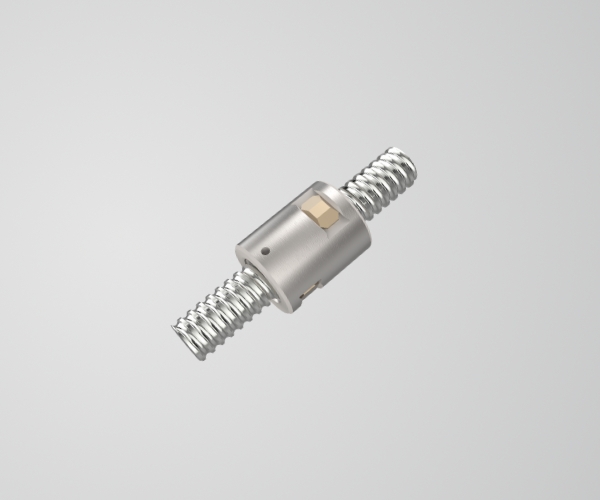

Steinmeyer ball screws are engineered to meet these demands without compromise. Designed for cleanroom use, they deliver reliable performance in dynamic environments and maintain exceptional stability and lifespan even in compact, highly integrated systems.

Let's talk about your project!

The perfect solution for every seminconductor system

Wafer production and handling

Processes like electron beam or EUV lithography demand maximum precision, stability, and material purity. Steinmeyer ball screws handle critical movements such as focus adjustments and wafer handling inside such cleanroom environments. Beyond their exceptional positioning accuracy, they stand out for their application-specific material configuration, engineered to minimize particle emission and eliminate contamination risks from dopants. Therefore they are the perfect fit for these highly sensitive manufacturing steps.

Inspection and metrology systems

When it comes to structural wafer inspection and high-precision measurements, every movement must be flawless. Steinmeyer ball screws provide precise feed and Z-axis positioning for sample stages and optical components. Built for cleanroom environments, they ensure smooth, vibration-free motion with exceptional accuracy and long-lasting reliability.

Assembly and Packaging equipment

In packaging applications like die attach, wire bonding, or flip-chip placement, fast and ultra-precise movement is essential. Steinmeyer ball screws enable sensitive alignment and feed motions—for example in pick-and-place axes or bonding heads. They support rapid cycle times with outstanding repeatability, even in continuous operation.

Why choose Steinmeyer ball screws

In semiconductor manufacturing, every detail counts. Even the tiniest contamination or deviation can disrupt processes, affect results, or lead to costly defects. That’s why it’s not just about precision — material quality and thoughtful design are equally critical.

Steinmeyer ball screws are engineered specifically to meet these high demands. They provide reliable, highly repeatable motion, whether operating in high vacuum, cleanrooms, or handling ultra-fine strokes. By carefully selecting materials, designing specialized nut geometries and customizing lubrication, Steinmeyer ensures these components perform flawlessly even in the most challenging conditions. This makes them indispensable for sensitive applications—from wafer production to optical inspection.

What makes the difference:

- Consistent precision thanks to flawless manufactured threads and application-specific preload settings

- Minimal particle emission through optimized material choices, with optional exclusion of defined doping elements

- Low outgassing and contamination-free operation using special lubricants and high-quality plastic components, with the option for completely lubricant- and plastic-free solutions in special cases

- Compact and efficient design featuring small nut geometries for highly integrated systems with tight installation spaces

- Optimized for vacuum and cleanroom applications thanks to tailored materials and application-specific lubrication concept

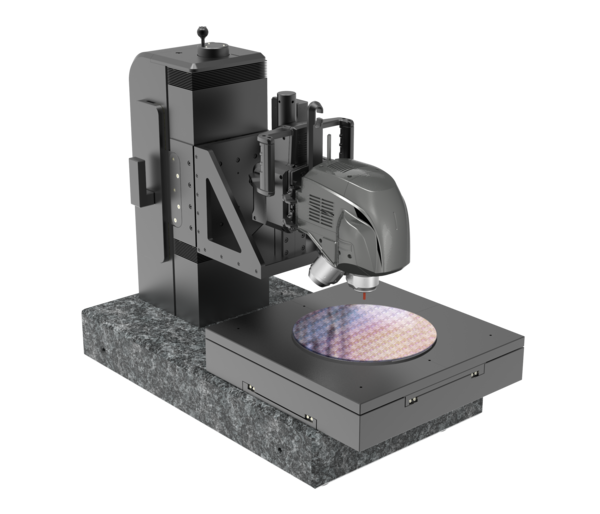

Case study: High-precision wafer inspection powered by Steinmeyer ball screws

In semiconductor manufacturing, success or failure is often determined by details measured in microns or even sub-microns. A custom-designed, modular XYZ positioning system from Steinmeyer Mechatronik provides the precise foundation needed to reliably align wafers up to 300 mm in diameter for inspection. Thanks to flexible mounts for interchangeable process heads like microscopes or sensors, the system easily adapts to a wide variety of tasks.

Designed for cleanrooms up to ISO class 6 and compatible with UV radiation environments, the system can also be tailored to meet higher cleanroom standards or handle other radiation types (including DUV, EUV, X-ray, and gamma) upon request. Additional features such as vibration isolation, built-in safety measures, and low-maintenance design ensure dependable operation around the clock.

At the heart of the motion and positioning axes are Steinmeyer ball screws. Perfectly matched to the system’s requirements, they provide smooth, precise, and repeatable movements. Even in demanding cleanroom conditions and continuous operation, they deliver consistent, reliable performance.

This blend of cutting-edge mechanics and carefully chosen cleanroom-compatible materials offers a solid foundation for complex inspection processes and the flexibility to adapt to a wide range of manufacturing needs.

Modular XYZ positioning system for wafer inspection

- Ideal for flexible inspection processes of wafers up to 12 inch / 300 mm

- Holder for exchangeable process heads (microscope, sensor, ...)

- Various scanning ranges and manual height adjustment (optionally motorized with motion controller)

- Low maintenance for 24/7 production up to cleanroom class ISO 6 (higher on request)

Options:

- Extendable travel range XY 200 - 350 mm, Z 200 - 400 mm

- Adaptation to the process: aperture, sample holder, extension of additional (motorized) Z-axes

- Adapted vibration decoupling by means of damping rubber intermediate layer or pneumatic dampers

- Safety concept and technology (emergency stop, door switch, light curtain, laser scanner, STO, SLS)

- Customized design with frame, enclosure or integration into the fab

- Customer-specific development with 3D design, prototypes, series production

FAQ - Ball screws for semiconductor

Are Steinmeyer ball screws suitable for cleanroom applications?

With tailored designs using specialized materials and optimized lubricants, Steinmeyer ball screws can be engineered to meet the requirements of various cleanroom classes.

How do the ball screws perform regarding outgassing and particle generation?

For cleanroom use, Steinmeyer relies on low-outgassing lubricants and high-quality components that minimize particle generation. For specialized applications, completely lubricant- and plastic-free solutions are also available upon request.

Can Steinmeyer ball screws operate under radiation exposure?

By selecting appropriate materials and lubricants, Steinmeyer ball screws can be adapted for use under various radiation types, such as UV radiation.

Does Steinmeyer also offer complete systems or customized assemblies?

Steinmeyer Mechatronik designs and manufactures modular positioning systems and ready-to-install assemblies, including drive, sensors, and controls, tailored precisely to your application. As a result, you receive complete turnkey solutions for positioning and handling, custom-built to your specifications and ready for use right away.