Lead-Offset Nut

![[Translate to English:] Kontakt](/fileadmin/media/steinmeyer/kontakt.jpg)

Contact

Under +49(0)7431 1288-0 we are at your disposal.

Your desired size is not listed? We also manufacture individually. Give us a call!

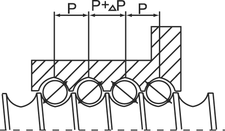

When preloading a UNILOCK double nut, the two halves are rotated relative to each other until the balls are slightly compressed. Thus the threads of the second nut are no longer directly "in phase" with the threads of the first nut. There is a slight offset between the two nut halves.

The lead offset nut uses the same principle but the offset is created during machining of the threads in a nut made from a single piece of steel. Fine tuning of the preload is then accomplished by selecting "oversized" balls like in a single nut. Due to the offset, balls have 2-point contact.

Advantage:

- Slightly more compact than a double nut (shorter length)

Disadvantage:

- More threads have to be machined from one end of the nut. Especially in nuts with many turns and large helix angle, grinding I.D. threads can be difficult or even impossible

NB: Steinmeyer often uses hard turning for such long nuts, eliminating the problems associated with long and relatively weak grinding arbors.