Preload Monitoring

![[Translate to English:] Kontakt](/fileadmin/media/steinmeyer/kontakt.jpg)

Contact

Under +49(0)7431 1288-0 we are at your disposal.

Your desired size is not listed? We also manufacture individually. Give us a call!

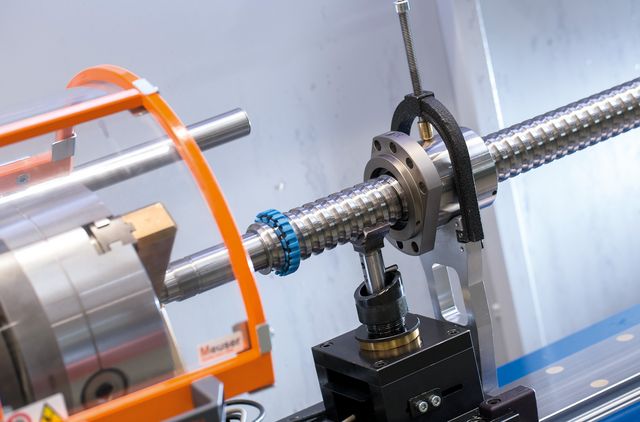

Direct and real-time preload monitoring.

Monitoring of Preload.

In machine tools industry, unexpected failures of ball screws is an expensive event. One of the most frequent failure modes is the loss of preload between shaft and nut due to abrasive wear of the ball paths and balls.

Preload is necessary to achieve position accuracy and rigidity of a ball screw.

Increased efficiency.

This wear can be measured directly using the new sensors and failure can be predicted. There is no need to rely on indirect monitoring via motor current or axis rigidity. Instead, the load on the ball path is measured by the roll contact. Potentially faulty OK from other components in the powertrain can thus be avoided..